Aquaculture may be conducted in coastal ocean waters, freshwater ponds and rivers, and even on land in tanks. Operators range from ‘hobby farmers’ to large, international corporations. It can be categorised according to the type of aquatic environment (eg. fresh, brackish or marine water), the type of production system used (eg. pond, cage, pen, raft, etc.), the level of intensity (extensive, intensive) or the type of organism cultured (eg. fish, crustaceans, molluscs etc.).

Suitability of species

Out of the thousands of marine species worldwide, only around 400 are commercially viable.

Identifying potential new species for aquaculture is an expensive and lengthy process as it requires extensive research into areas such as reproduction and larval development, feed and nutrition, responses to stress, welfare and pathology, and formulating solutions in each of these areas.

In aquaculture, economic viability and presence of proven technologies is of primary importance to potential investors. In general, there are seven key considerations that determine whether a species is suitable for commercial farming:

- Growth and production rate. A faster rate of growth is preferable, especially when considered in relation to feed efficiency – although slower growth species may be suitable if they have a high market value.

- Size and age at maturity. Generally, species which reach marketable size before attaining first sexual maturity are preferable as most of the feed would be used by them for growth.

- Breeding. Important factors include availability of seed in the wild, success of breeding in a captive environment, fertility rates and frequency of spawning, acceptance of artificial feed by larvae and survival rates of egg, larvae, juvenile and adult stock.

- Adult feed. What feed is required, how much is needed and what will it cost. Herbivorous and omnivorous species are usually preferable. Some species can feed on natural organisms in the water, which can be increased at relatively low cost through fertilisation and water management. Fish which accept artificial feed may also be suitable, as can carnivorous fish which fetch a high market price.

- Resistance to disease. Suitable species are those which are most tolerant to pathogens, potential water quality issues and fluctuations of temperature and oxygen concentrations.

- Influence of species on the environment. If an aquaculture species affects the ecological balance to a significant degree it might not pass environmental regulation assessment and/or might require costly protective and maintenance measures. This is particularly an issue for introduced species.

- Suitability for intensive or semi intensive culture. Species that can withstand a confined, high density environment – and associated potential issues such as cannibalism in the early stages – is considered most suitable.

Aquaculture process

The method in which an organism is farmed varies according to the species. However, as a rule the process involves the following stages:

Hatching

This stage encompasses breeding and raising aquaculture products for the first part of their life cycle. Hatcheries hold adult brood stock that are manipulated under controlled conditions to induce spawning, which results in the production of eggs and larva. Typically, a hatchery would consist of a brood stock holdingand spawning area, feed culture facility, larval and juvenile culture areas, pumps, laboratories and quarantine

areas.

Some aquaculture operations have their own hatcheries which produce their own juveniles, while others rely on stock produced by independent hatcheries.

In some cases, hatchery stock is released into the wild rather than a farm (eg. in WA, 80% of trout raised in hatcheries is grown to provide stock for recreational fishing).

Farming

When organisms are large or old enough, they are transferred to a farm where they are held until harvest stage. They are protected from predators and fed regularly (unless they are filter feeders). There are different types of farming systems, chosen according to the species raised, location, and finance available. Examples include:

- water-based systems (cages, pens, floating lines or baskets, inshore/offshore;

- land-based systems (rain fed ponds, irrigated or flow-through systems, tanks and recirculation systems);

- recycling systems (high control enclosed systems, more open pond based recirculation);

- integrated farming systems (e.g. livestock-fish, agriculture and fish dual use aquaculture and irrigation ponds).

Post-harvest handling

This is where the product is processed, packaged and prepared for market. The processing can include live transporting, salting, smoking, drying, fermenting and canning.

The methods and processes employed in this stage of aquaculture are dependent on:

- consumer taste

- technical knowledge

- price of the final product

- costs of processing

- storage and transport facilities

- seasonal variations

Figure 1. Mussel harvesting barge at Oyster Bay, near Albany

Aquaculture types

Sea ranching

Suitable for: shellfish echinoderms and coelenterates Eg. Abalone (Flinders Bay near Augusta)

How it works:

- Juveniles (either wild caught or hatchery produced) are placed in location eg. on artificial reefs or sea bed and allowed to grow to marketable size.

- Feed naturally, with no input from the farmer.

- Only viable if the culture area is closed to commercial fishing.

Figure 2: Abalone growing on artificial reef in the South West

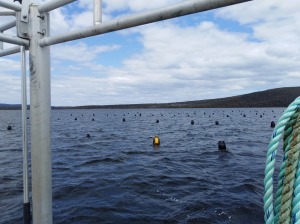

Line and rack systems

Suitable for: shellfish, tunicates, seaweeds and sponges eg. Oysters (Pilbara, Albany and Cockburn Sound)

How it works:

- Filter feeding species grow in baskets, cages or racks.

- The cages are suspended from long lines that float on the sea surface supported by buoys and anchored to the seabed.

- Lines are kept taught and well-spaced to reduce entanglement, allow good flushing and good light penetration to the seabed below.

- In the case of the line systems, there are no obstacles on the sea bed, bar at the anchor points, and normal processes can take place below the farm.

Figure 3: Oyster and mussel farming at Oyster Bay, near Albany

Sea cages

Suitable for: Finfish and crustaceans eg. Barramundi, Kimberley

How it works:

- Pens, or cages, are anchored in estuaries, bays or other marine environments. The farms use natural currents to provide oxygen, remove waste – and give fish an opportunity to ‘exercise’ by swimming against them.

- Design and size of the cages depends on the culture species, site conditions and environmental features. They can be made from nylon mesh, PVC-coated polyester, brass or galvanised steel. The stronger materials help prevent predation from other species, such as sharks.

Figure 4: Barramundi sea cages in the Kimberley

Pond or tank system

Suitable for: Usually used for crustaceans and finfish eg. Yabbies and marron (South West WA)

How it works:

- Earthen pond, dam or ditch, or tanks made of concrete or fibreglass.

- Constructed inland, near the coast, estuaries or river systems.

- Water is pumped into the farm and gravity fed into a series of production ponds. Water drains from the ponds and enters a treatment pond where solid wastes settle before the water is discharged or processed (eg. it can be converted to fertilizer). Some might be recirculated back into the farm system.

- Purpose-built ponds have a gently sloping bottom to allow for harvesting and full drainage if needed.

Figure 5: Marron Pond. The pond can be drained for harvesting. Note the mesh above and around the pond to prevent bird predation and marron escaping.

Recirculating system

Suitable for: Diverse species, particularly used in hatcheries

How it works:

- Indoor, tank based system where organisms are grown at high density under controlled conditions. Specific design depends on the species cultured.

- Useful for where suitable land and water is limited or where the local environmental conditions are not suitable for the species being cultured.

- Intensive aquaculture technique which typically involves large set up and operating costs (eg. requires close monitoring of water chemistry, mechanical and biological filtration, aeration, disinfection, temperature control, etc).

Feed and feeding

Feed quality affects the growth and health of cultured organisms. It can also account for more than half of the total costs of production, so it is a significant consideration within the aquaculture process.

Aquaculture usually requires some form of artificial feed (apart from filter feeding molluscs). These feeds usually contain fish meal and fish oil which often comes from small pelagic fish such as herring, anchovies and sardines. Other ingredients include agricultural products including corn, poultry and soy.

Different species have different nutritional requirements, so feed is developed specifically to meet the needs of each species. Other additives might be used to ensure that the nutrients contained within the artificial feed are ingested and digested, that growth, development and health of stock is maximized and that the feed can be commercially stored. These additives might include binders, preservatives and enzymes, probiotics or immune stimulants.

Figure 6: Bags of algae that had been cultured as feed for shellfish at the Western Australian Fisheries and Marine Research Laboratories, Hillarys.

Commercial viability

Governments can support and oversee aquaculture through regulation, research and provision of research based advice, economic incentives and other means. However, the aquaculture industry is primarily based on individual or corporate ownership of stock being cultivated, and as such it is driven by a goal to maximise yield and/or profit.

The yield, commercial viability and economic sustainability of aquaculture industries is determined by complex factors, which include, but are not limited to:

- environmental constraints

- processing and production technologies

- transport costs and efficiency

- production costs (eg. power, capital, labour costs, feed costs)

- market supply and demand

- competition

- diversity and health of species

- availability of credit

References

Aquaculture Alliance, www.aquaculturealliance.org

Department of Agriculture, Water and the Environment, Aquaculture industry in Australia https://www.agriculture.gov.au/fisheries/aquaculture

Food and Agriculture Organisation of the United Nations, Aquaculture systems and species, http://www.fao.org/3/AB412E/ab412e07.htm

Department of Primary Industry and Resource Development, Aquaculture position paper, aquaculture_position_paper

Oceanwatch Australia, Aquaculture, https://www.oceanwatch.org.au/seafood/aquaculture/

National Oceanic and Atmospheric Administration, Feeds for aquaculture, https://www.fisheries.noaa.gov/insight/feeds-aquaculture

GoodFishBadFish, Aquaculture methods, http://goodfishbadfish.com.au/?page_id=33